What is glass bonding?

It is the joining of glass edges and surfaces glued together with a transparent adhesive, which sets (or cures) by exposure to ultraviolet light. The sequence is where the term UV glass bonding comes from; it is also possible to bond metal fittings to glass.

Typically, shelving units and furniture are produced in this way, although there are certain limitations so far as weight bearing is concerned.

What you can achieve with UV bonding

Our UV bonding facilities enable us to join all kinds of glass and mirrors clearly and seamlessly, without an obvious glue-line. We can: fix shelves to mirrors, splashbacks, a shower enclosure and more. Also, we can produce:

- glass containers

- furniture

- artworks

- showcases

- bookcases

- display aids

- serving displays

We use low iron glass to reduce green tint

When you see the edges of the bonded glass, they can appear green if the low iron-type glass isn’t used. This tint can add an aged effect which you might like, however, if you don’t, and you want a clean finish, we can happily provide.

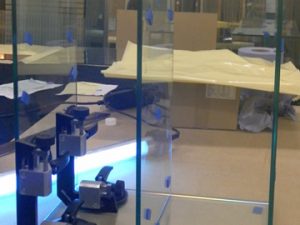

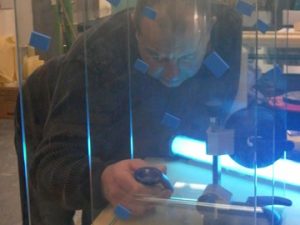

The production of glass showcase

- The adhesive, which sets (cures) with ultraviolet light, is run into the joints to be bonded.

- We use suction-cup clamps to hold the glass panels of the showcase (usually in toughened glass with polished edges) in position.

- Finally, we apply the adhesive, which is entirely invisible.

Your supplier in London

We manufacture and install in and around South London. Check out our areas covered page to see if we serve your local area. Can’t find it? Pick up the phone and ask us personally!